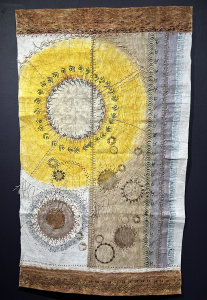

The ʻAi Pōhaku, Stone Eaters exhibition opened at Windward Community College’s Gallery ʻIolani on March 31. The exhibition features the collaborative work of Hawaiian artists, curators and educators. Gallery ʻIolani is the latest stop of the multi-site exhibition, which will continue to unfold at venues across the UH Ssystem throughout this year.

- Related UH News story: Kānaka ʻŌiwi art spanning generations showcased in new exhibition, February 27, 2023

“ʻAi Pōhaku, Stone Eaters affirms our long-standing acts of creative resistance and persistence. Emerging collaboratively, this multi-site exhibition is guided by ongoing conversations with family, friends, mentors, and colleagues—all of whom have contributed to a larger movement toward self-determination within the arts of Hawaiʻi,” said co-curators Drew Kahuʻāina Broderick (Koa Gallery, Kapiʻolani CC), Noelle M.K.Y. Kahanu (assistant specialist, UH Mānoa American Studies) and Josh Tengan.

The exhibition at Gallery ʻIolani will feature pieces by the following artists:

- Meala Bishop

- Solomon Robert Nui Enos

- Roen Hufford

- ʻĪmaikalani Kalāhele

- Lehuauakea

- Nanea Lum

- Tiare Ribeaux

- Maikaʻi Tubbs

The exhibition is supported by the Puʻuhonua Society, Admiral Residency in Contemporary Pacific Art, Hawaiʻi State Foundation on Culture and the Arts, Native Arts and Cultures Foundation, Institute of Museum and Library Services and Independent Curators International.

The ʻAi Pōhaku, Stone Eaters exhibition at Gallery ʻIolani is on view through May 5. The gallery is open Monday–Friday and Sunday, 1–5 p.m.

To learn more, visit the Gallery ʻIolani website.